Client Background

The client provides engineering services and a focused range of performance-enhancing Atmospheric Gases, Welding and safety products and LPG to valued customers. Given the criticality of the services offered by the client, transformers in all electrical networks must be kept to a highly reliable and maintainable standard to prevent premature failure. Transformers play a key role in power distribution. Therefore, should the client experience downtime of Transformer T9, the result would be a loss of production and severe repair or replacement costs.

Upon inspection of Transformer T9, Martec identified damaged cables connected to the transformer via a link box. Online and offline assessments were conducted to verify the condition and the results revealed high-level discharges within the Transformer T9 power circuit.

Key Challenges

Damaged cables, it was found that cables between the link box and transformer were extremely damaged due to attempted theft, this created high partial discharges.

Excessive oil leaks were identified in Transformer T9. The oil leaks present a risk of moisture and air being drawn in via capillary action, compromising the transformer oil insulating qualities. Oil leaks from the transformer bushings contribute to surface/ tracking discharges.

Martec Intervention

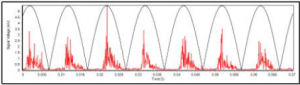

Martec installed temporary cable joints to bypass the link box so that the links can be refurbished. Online assessments were conducted to verify the installation, and the results revealed persistent surface discharges which are attributed to the oil leaks on the transformer bushings. Furthermore, infra-red scanning was conducted and revealed slightly elevated temperatures of the transformer oil. An oil sample will be taken for Dissolved Gas Analysis to verify the insulative status of the transformer oil. Martec installed a permanent intime monitoring solution to closely monitor the transformer over time. Upon breached thresholds, alarms will be raised to notify relevant personnel of potential defects ahead of time and prior to complete failure.

Value add

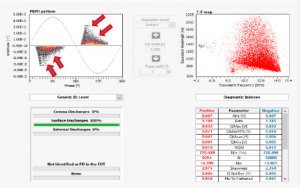

- Martec conducted an online assessment using the advanced Aquila and PDFSA technologies.

- The Aquila technology utilises a PD analysis software tool called TF mapping, which allows for effective separation of external noise and detection of PD even at or below the noise level.

- Both technologies are able to identify different types of PD phenomena such as internal, surface and corona PD.

- Moderate to high surface PD signals were detected during online condition assessment which presents a high risk of failure.

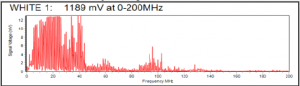

PDFSA Signals

Tools and Technology

- Aquila PD assessment Technology

Partial Discharge Frequency System Analyser (PDFSA)

Ultra Sound and Infra red Scanning

Visual Inspections

Investigations