Client Background

A client working in the renewable energy space approached Martec to provide a condition assessment of around 800 Type “C” terminations in operation at various solar plants in South Africa.

It is important to conduct these assessments when the plant is subject to the full combination of thermal, electrical and mechanical stresses whilst in service.

Key Challenges

The key challenge during the installation of the type “C” terminations are to follow to correct installation instructions. It was during our assessment that we found this had not taken place. It was necessary for quality control to be undertaken at each and every termination to determine the level of degradation.

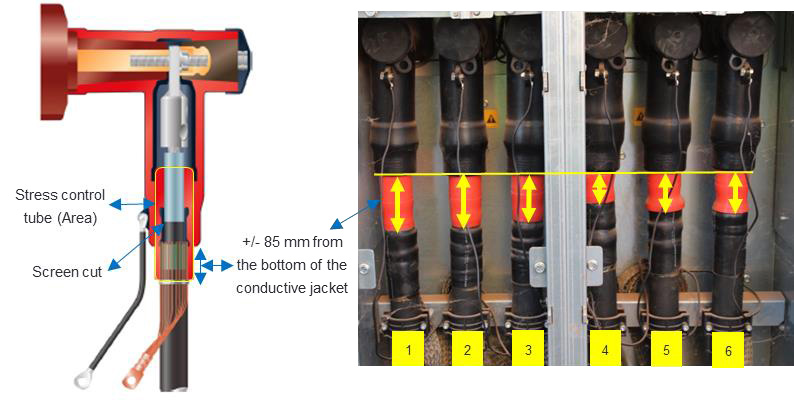

The photograph, shows the installation of six single core type “C” terminations in two cubicles next to each other. In this case indicated by the yellow arrows, it can be seen that the stress control tubes are not the same length from the outer conductive jacket and will lead to failure.

Martec Intervention

- In-time condition assessments (In-time, is assessments performed during plant operations) were conducted on around 800 type “C” terminations.

- A high failure risk of the type “C” terminations was identified and communicated to the client using technical reports with recommended corrective actions.

- The partial discharge assessments were conducted in a non-intrusive manner.

Value add

- Identifying defects that could turn into unwanted premature failures and down time.

- Improving the safety of personnel during switching operations of the electrical plant.

- Picking up defects to be repaired before plant commissioning.

- Quality control interventions will add to reliability of the plant.

Tools and technology

- Frequency System Analyser

- Tan Delta

- VLF testing

- Partial Discharge mapping

- Quality assurance procedure

- Infrared scanning

- Ultrasound scanning

- Cable system analyser

- In-time condition assessment process