Client Background

Organisations using electrical furnaces know that the furnace is the heart of the production process and must have a reliable supply of power at all times. Our client relies on smelting furnaces to run some of their operation and they are well aware of the impact and downtime costs related to failures of the furnace MV switchgear cables and terminations.

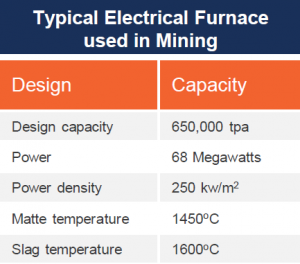

The table describes a typical electrical furnace that is used within the South African mining market.

Key Challenges

- Our client experienced failure on their electrical smelter.

- Very high electrical partial discharges activity was identified on furnace cable terminations while performing PD diagnostic analysis of the online monitoring data.

- Potential defects were monitored until an emergency shut was arranged for further inspection and investigation.

- We replaced two terminations with the highest discharges. Investigation and tests were conducted on the two terminations to determine the root cause of the discharges.

- An in time PD monitoring system was installed on the 33 kV switchgear to measure electrical partial discharges within the switchgear components.

Martec Intervention

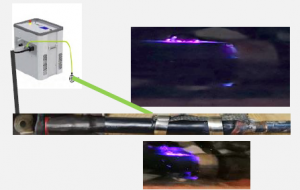

Martec conducted an investigation of the 33kv cable terminations. High voltage 50hz was applied to the termination.

The termination earth strap was folded over the black heat shrink tube and secured with roll springs. Tracking discharges were identified on the black heat shrink tube.

The screen cut of the terminations were found to be incorrectly installed. Voids were identified between the screen and XLPE insulation. Discharges could be identified at phase voltage.

Value Add

- Martec started with partial discharge diagnostic, the staff was trained by international experts to conduct diagnostic of PD phenomena’s that could turn into unwanted premature failures and down time.

- Martec implemented various advance partial discharge technologies within the market to enhance reliability of the MV power plants.

- The main focus of these technologies were to identify premature failures and improve the safety of the switchgear during switching operations.

Tools and Technology

- Frequency System Analyzer

- Aquila Advanced Diagnostics

- Dynamic Rating (In Time Monitor)

- Visual inspections

- Permanent sensors