Client Background

A large independently operated and managed, black empowered manganese ore producer finds themselves under constant pressure to meet production demands with a single line from crushing to load out for export. A machine failure on the line results in high repair costs as well as downtime, which imposes significant risk.

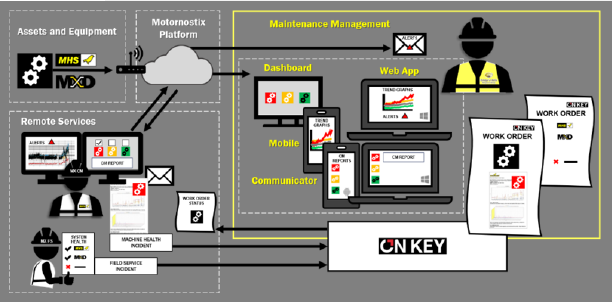

To ensure the deliverables are met in a safe and responsible manner, producer adopted effective maintenance management principles. This decision led to the journey of condition-based maintenance. An automated condition monitoring solution integrated to the existing Enterprise Asset Management System provides machine condition assessments and triggers workflow notifications with recommended corrective

actions.

Key Challenges

- Machine failures proved costly considering downtime and resource planning to maintain the status quo.

- Scheduled periodic assessments on the critical assets were not reaping the expected benefits, which resulted in more frequent assessments with a high cost.

- Poor analysis reporting with indecisive recommendations contributed to the performance of unconcise maintenance tasks.

- Defect notifications were not communicated effectively.

Martec Intervention

- Identified critical areas with the client to roll out a cost-effective condition monitoring system.

- Identified vibration, acoustic emission, speed and temperature as valuable measurables related to common failure modes experienced on the assets.

- Implemented in time condition monitoring systems with diagnosis capabilities on critical assets and basic trending of significant parameters other identified plant assets.

- Provides skilled resources to remotely assess and diagnose machine defects.

- Hosts history of machine defects, failures, alarms, diagnosis and repairs.

- Integrated the in time monitoring system with the existing Enterprise Asset Management System for maintenance planning.

Value add

- Machines are monitored in near real time.

- Warning and alarm levels are configured for triggered analysis activities to commence.

- Skilled analysis service is provided remotely, minimising call outs.

- Communication is provided via visualised dashboards accessible via any internet connection by authorisation logins.

- Notifications are raised to persons responsible for the plant area.

- Automated maintenance management systems prove reduced task planning required, with fewer resources and less time.

Tools and technology

- Machine Health Surveillance (vibration, acoustic emission, speed and temperature)

- Web Analysis application (diagnosis and trending)

- Communicator (online reporting)

- On Key Enterprise Asset Management System