Client Background

Martec conducted comprehensive online partial discharge (PD) and offline (VLF, tan-delta and PD) assessments at two wind farms in southern Africa. One wind farm can generate approximately 341,000 MWh of renewable energy annually, preventing around 384,000 tons of carbon emissions from fossil fuel power plants.

Conducting condition assessments at these plants to ensure continuous and reliable operation is paramount.

|  |

Key Challenges

- Contamination and moisture ingress can lead to partial discharge.

- Circulating currents on single-core cables due to improper installation.

- Medium voltage (MV) joints and terminations not installed under quality assurance processes can lead to premature equipment failures.

Findings and Observations

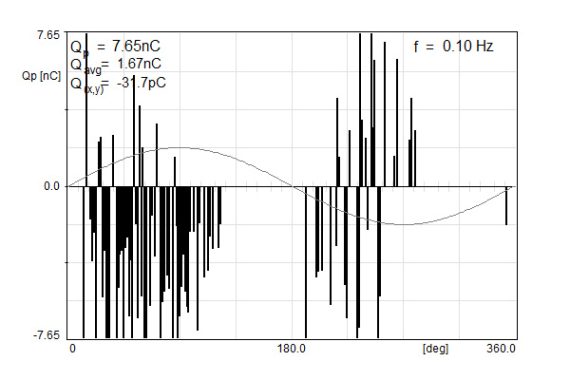

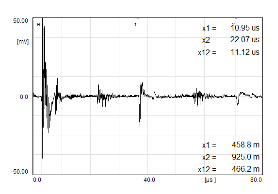

- Well-defined PD patterns were identified during the online assessment.

- Visual inspections identified signs of PD on the “C” type connectors.

- Signs of leakage current defects were identified on the terminations of the main transformers.

- PD levels higher than acceptable limits were detected during the offline assessment of the cables.

Martec Intervention

- Martec conducted a comprehensive online PD assessment using advanced technologies to ascertain the overall condition of the plant.

- A visual inspection was done to identify signs of PD on the assessed components.

- On another wind farm, Martec conducted an offline (VLF, Tan-Delta and PD) assessment on feeder cables.

PD levels of up to 3825pC were detected coming from the cable terminations. |

Value Add

- The online assessment was conducted with the plant running normally, thus not negatively affecting production targets.

- More advanced technologies that can detect electrical discharges within the switchgear and terminations were utilised.

- The VLF, tan-delta and PD assessment detected defects from cable terminations.

- Visual inspection identified defects before they could turn into failures.

- Risk condition levels were assigned to the assessed components.

Tools and Technology used

- Partial Discharge System Analyser

(PDFSA) - Ultrasound

- Visual inspections

- Open-end PD sensors

- Offline (VLF, tan-delta and PD ) test equipment

- Implementing risk interpretation guidelines