Asset health management on transformers

Want to mitigate the risks posed by your transformer failing and leaving your plant without power when you need it most?

Martec provides an engineering support service that provides:

- Improved transformer availability

- Extended asset life

- Reduced business interruption risk

- Increased cost transparency and predictability

- Lower business risk

All electricity users and plant owners are dependent on their transformers to keep their plants or networks in operation. Transformer failures can be catastrophic and dangerous and lead to a loss of revenue, products, service delivery, income, brand equity and much more.

By continuously monitoring these assets you have factual and in-time information about their condition and are able to make quick decisions and take actions, to ensure their availability.

For us, it is more than just monitoring

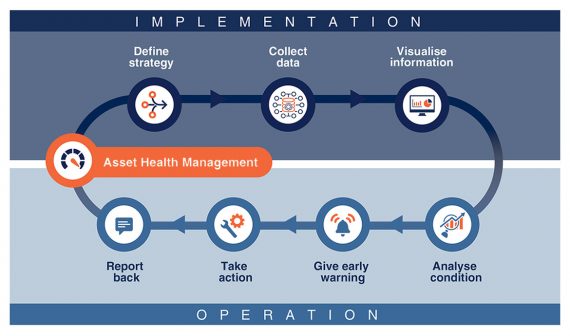

We follow an end-to-end implementation and operation’s approach to asset health management that includes a structured framework with asset type-specific features.

Our scope

Assets we cover

- Transformer

Industries we serve

- Utilities

- Generation and Transmission

- Mining

- Manufacturing

- Renewables

Your challenges

Transformer reliability

- Degradation or contamination of oil insulation

- Overheating and thermal degradation

- Low insulation and cooling oil levels

- On load tap changer failure

Transformer risk

- Business interruption and long repair/replacement lead time in case of failure

- Potential for catastrophic and harmful failures

- Lack of redundancy or mitigation plans

Impact vs Probability

- Complacency due to low frequency and high reliability of transformers

- Limited consideration for the high impact in case of failure

Impact of poor maintenance practices

- Statutory compliance work not tracked

- Remedial work not managed

- Maintenance work quality not confirmed

- Reduced asset reliability

Our value

Improved business sustainability

- Risk of failure reduced due to early detection of potential faults

- Business interruption risk mitigated through in-time monitoring and expert reliability advise

- Accurate and reliable information delivered to the right people, in the right format in-time

Transformer availability assurance

- Transformer health parameters monitored and early warning provided

- Reactive and predictive maintenance work identified, planned and executed by expert field technicians

- Contractors dispatched to perform work under agreed SLA

- Maintenance work inspected to ensure quality

- Effective management and control of maintenance contractors

- Critical information provided to enable agile decision making

- Advanced diagnostics on-site to support fault finding efforts and take corrective action before failure

- RCM based maintenance plans

Improved cost transparency

- Maintenance spend planned, benchmarked and controlled

- Reduced fixed-interval maintenance – only act when required

- Asset life-cycle cost managed based on reliable information

- Consolidated monitoring, reliability, advisory and maintenance service

Best-in-class monitoring solution

- Intelligent Gateway that bridges the gap between edge devices and the cloud

- Web-based IIoT monitoring platform for easy and remote access to condition parameters

Focus on Transformers

What we monitor

Temperatures

- Top & Bottom Oil

- Cooler Oil / Water

- Winding Hot Spots

- Ambient

- Terminations

Bushing Health Tan Delta and Capacitance

Cooling System

- Fan/Pump Current

- Status Inputs

- Loss of Power

System Health Monitoring

- Internal Self-Checking

Partial Discharge

Tap Changer

- Position

- Operation Counters

- Temperature Differential

- Drive Motor Monitoring

- Contact Wear

- Reversing Switch Operation

Voltage Regulation

On Line DGA and Winding Temperature

- DGA and Moisture

- Fiber Optic Temperature

Harmonics and Fault Occurrences

Load monitoring