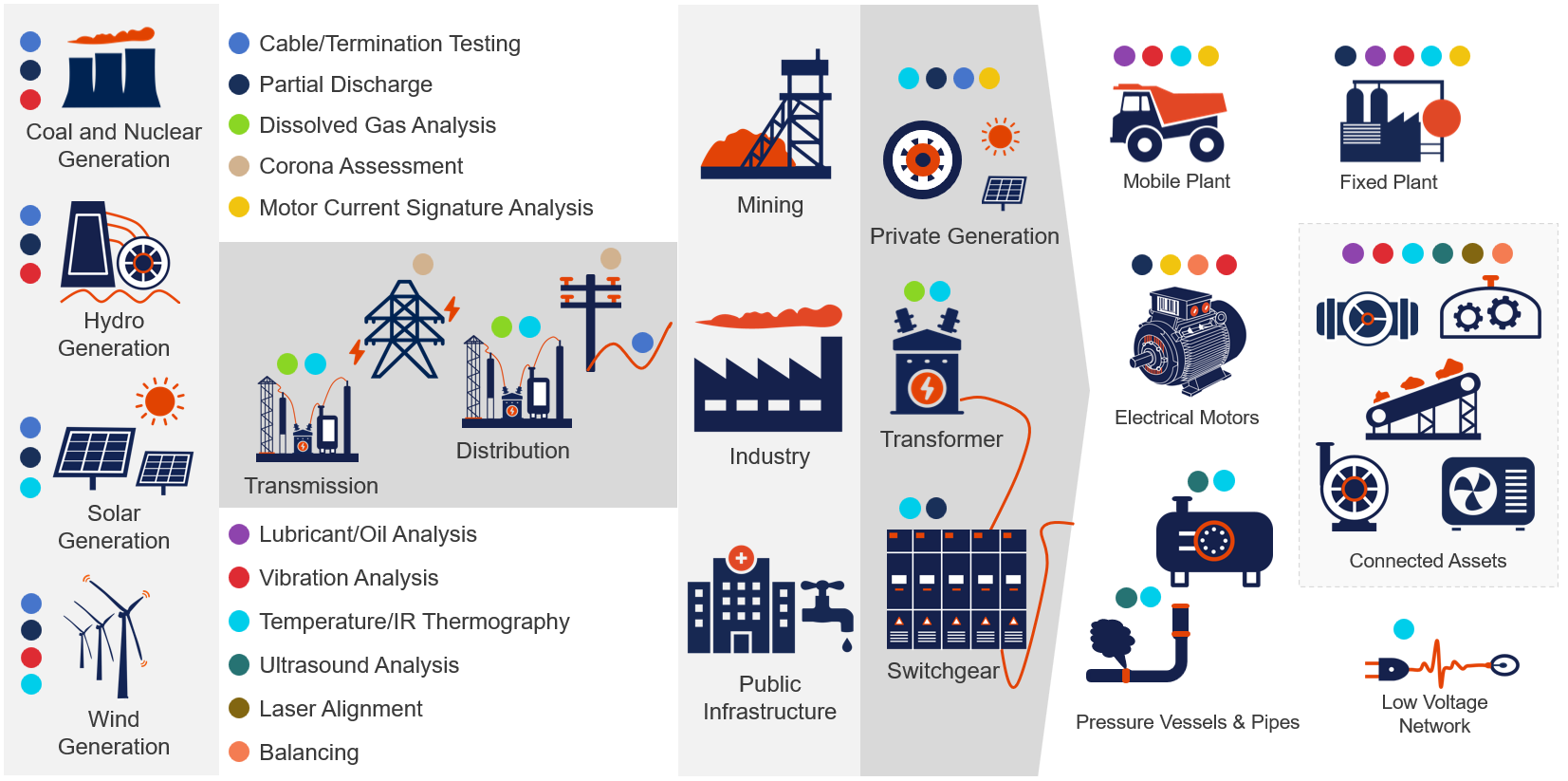

Condition Monitoring technologies and systems

Are you responsible for the reliability and productivity of an asset-intensive plant? Are you tasked to improve the bottom line at a mine despite aging equipment? Are you maintaining remote and dispersed utilities? Whatever your challenge, you can take control and succeed with the right blend of CM technologies in place. We will help you make the right choices about CM technologies and hardware that will suit both your equipment and budget.

Are you using the right CM & IIoT technologies for your plant?

Let us help you make an informed decision that will meet your needs.

Speak to us about your technology road map

Which technologies to use?

With a range of CM technologies to choose from, you need to thoroughly assess the overall requirement for your plant before establishing the niche requirements for specialised assets.

Based on these requirements, you have the option to:

- purchase your own CM equipment

- rent to own CM hardware/sensors to cover more assets rapidly

- contract Martec to perform service assessments for you.

Speak to us for a thorough assessment and a technology road map to ensure that you have the right equipment in place for your asset management and reliability tactics.

Condition monitoring products and technologies

Martec is the official (in some cases, the sole) representative of more than 20 CM technology suppliers in Southern Africa.

Product Technology

Vibration analysis

Vibration Analysis is the process of measuring the vibration levels and frequencies of industrial machinery and using that information to determine the ‘health’ of the machine and its components. Defects such as imbalance, vibration, temperature, bearing failures, mechanical looseness, misalignment, resonance and natural frequencies, electrical motor faults, bent shafts and gearbox failures can be identified.

Application

- Bearings

- Motors

- Gearboxes

- Fans

- Conveyor belts

- Pumps

- Proximity cables

- Shaft vibration

- Displacement on mechanical applications

Brands we represent for this product

Ultrasound Structure and Airborne

Airborne or Structure Borne Ultrasound is a predictive maintenance and energy conservation technology used to locate leaks, detect electrical emissions and inspect mechanical conditions in operating equipment. T technology has a vast array of applications including leak detection (compressed air, vacuum, fluids), assessing bearing CM and optimum bearing lubrication levels, identifying electrical discharges such as arcing tracking and corona, bypassing valves, defective steam traps, and hydraulic defects.

Applications

- Lubrication

- Bearings

- Valves

- Hydraulics

- Substations

- Compressed air

- Motors

- Fans

- Gearboxes

- Pumps

- Tank testing leaks – underground and surface

- Marine leak detection on ships

Brands we represent for this product

Temperature Monitoring

Infrared thermography is the process of using a thermal imager to detect radiation (heat) coming from an object, converting it to temperature and displaying an image of the temperature distribution. Application includes identifying hotspots on distribution boards, mechanical equipment (friction), electrical motors and bearings.

By using a high sensitivity ultraviolet camera, corona and surface partial discharge activity can be identified on MV and HV electrical assets such as transmission lines, HV bushing connections and string insulators.

Applications

- Mechanical – IR bearings, fans, motors, gearboxes, furnaces, etc

- Electrical IR and UV – transmission lines, power transformers, switchgear, electrical panels, DB boards

Brands we represent for this product

Breaker Performance Monitoring is ideally suited for implementing predictive maintenance, maintenance deferral, condition-based maintenance and increased environmental protection from SF6 gas leaks. It monitors the condition of the main contacts, mechanism and dielectric, and logs the following information during circuit breaker operation:

- Trip Time (ms) (also known as Opening Time)

- Arc duration (ms) (phase segregated)

- Clearing Time (ms) (also known as Interrupting Time)

- Cumulative I2 x T or I x T on the main contacts (phase segregated) from arcing

Restrike Occurrence (phase segregated) - Operation Counts

Brands we represent for this product

Transformer Oil Monitoring and Analysis

Oil analysis is the internationally recognised standard method for monitoring the condition of transformer oil and insulating paper and obtaining an early warning of internal transformer problems. Online DGA monitors allow for in-time monitoring and sampling of oil to trend and diagnose any abnormalities, preventing unplanned transformer failures.

Applications

- Power transformers

Brands we represent for this product

Shaft voltage and current monitoring

The purpose of shaft voltage and current monitoring technology is to indicate and then mitigate the effects that high levels of voltage or current have on the motor or generator shaft.

Variable frequency drives (VFDs) on AC and DC motors create harmful electrical voltages on the motor shaft. If these voltages build up too much they will discharge through the motor’s bearings causing fusion craters, severe pitting, and fluting. Excessive bearing noise and eventually premature bearing failure is the result.

Applications

- Large generator

- Bearings

- Journals

- Sleeve bearings

- Shafts

- Pipe lines

- Housings

- Turbines

- Motor and generator excitation systems

- Generator shaft voltage protection

- Slipring truing on generators

Brands we represent for this product

Partial discharge analysis

Partial Discharge (PD) activity is a factor in approximately 85% of substation failures. PD activity provides evidence that an asset is deteriorating in a way that is very likely to lead to catastrophic failure. The process of deterioration can increase until the insulation can’t withstand the electrical stress any longer. This results in flashover or failure of the electrical asset.

PD analysis gives an accurate picture of the condition of electrical assets. The risk of the assets failing immediately can be assessed, or failure in the future can be predicted.

Applications

- Power transformers

- Motors

- Generators

- Switchgear

- Cables

- Bushing on transformers

Brands we represent for this product

Test and Measurement

For electrical test and measurement applications we offer a complete range of equipment including:

- Cable fault, test and diagnostics/Cable fault and test system vans

- VLF, Tan Delta and PD test equipment

- Transformer test equipment

- Circuit breaker test equipment

- Circuit breaker analysis systems

- Electricians’ testers

- Insulation test equipment

- Motor and generator test equipment

- Relay and protection test equipment

- Resistance, battery and power quality equipment

Applications

- Electrical, mechanical, process equipment and plant

- Multimeters

- Insulation resistance

- Temperature

- Alignment

- Process and instrumentation

- Power transformers

- Motors, DB boards, electrical panels, earthing systems

- Circuit breakers, protection relays, cables

Brands we represent for this product

IIoT Sensors and Accessories

Sensors and accessories for in-time and IIoT monitoring including both mechanical and electrical applications. Sensors, cables and hardware for the following technologies are available

- Vibration sensors

- Proximity sensors

- Ultrasound sensors

- Temperature humidity and partial discharge sensors

- IIoT Raptor Gateway for edge processing and data visualisation

Applications

- Substations

- Motors

- Generators

- Switchgear

- Cables

- Transformers

- Bearings

- Pumps

- Fans

- Conveyors

- Circuit breakers, cables, busbars, transformers

Brands we represent for this product

SF6 Gas Analysis

Quality SF6 analysis has three main purposes:

- To establish that the quality of gas meets the intended equipment service conditions at the time of commissioning (or at any other moment of manipulation of the equipment e.g. SF6 filling or replenishment during service).

- To diagnose the deteriorating condition of any SF6 filled equipment during its service handling and consequent disposal (internal arcing, moisture ingress, etc).

- To evaluate the insulation properties of SF6 gas including purity, moisture and breakdown products.

Applications

- Circuit breakers

- Gas insulated switchgear

- Gas filling circuit breakers switchgear

Brands we represent for this product

VLF and Tan Delta Testing

Very low frequency (VLF) tan delta testing is a precise and non-destructive method to provide information on the extent of ageing in cable insulation (both paper and XLPE insulation). The test applies an AC sinusoidal waveform at 0.1 Hz frequency and measures the degree of real power dissipation (or losses) in a dielectric material. The test determines the integrity of the insulation properties of cables, bushings, etc. Tan delta testing is performed with the cable offline and is a new test specified for diagnostic purposes in SANS 10198.

Applications

- MV and HV cables

- Busbars, switchgear

Brands we represent for this product

Acoustic Emission

Acoustic Emission (AE) technology ‘listens’ to your equipment, using specialised sensors to detect discontinuities. Discontinuities and defects in a material produce stress waves, which then propagate to the material’s surface and are picked up by the active AE sensing technology. By converting these waves into electrical signals, AE is an ideal technique to effectively assess the behaviour of materials under stress. examples include tube leaks in boilers and feed water heaters,, internal discharge in transformers and defective valves.

Applications

- Large power boilers, feed water heaters and coal flow

- Power transformers

- Bypassing valves, gas, steam and liquids

Brands we represent for this product

Fibre-optic Distributed Sensing

This is a very specialised technology with many uses such as non-intrusive measuring of flow in pipes, distributed temperature monitoring of electrical cables, and vibration detection (for instance cable theft). The fibre cable is used as a sensor and measures parameters such as temperature, flow, vibration or acoustic sound.

Applications

- Cable temperature monitoring

- Cable theft monitoring

- Cable flow measurement and vibration

- Switchgear

- Fire detection in tunnels

- Fire detection and monitoring of conveyor belts

- Vessels

- Tanks

Brands we represent for this product

Technology Support

Do you experience difficulties with your CM technologies and equipment?